How to Make a Wool Pom Pom Hat

To continue sharing the processes that go into making Collingwood-Norris knitwear, I thought I would show you how one of our new patterned lambswool hats are made.

The Finest Quality Lambswool

As you may know by now, I start by selecting the best materials. These wool beanie pom pom hats use a heavier weight lambswool than our other products, but it is the same high quality wool that is spun and dyed in Kinross, and it's incredibly soft- ideal for a hat! I love picking the colour combinations- this hat uses lots of rich warm colours which I always enjoy knitting with.

Lambswool on cones, ready for knitting

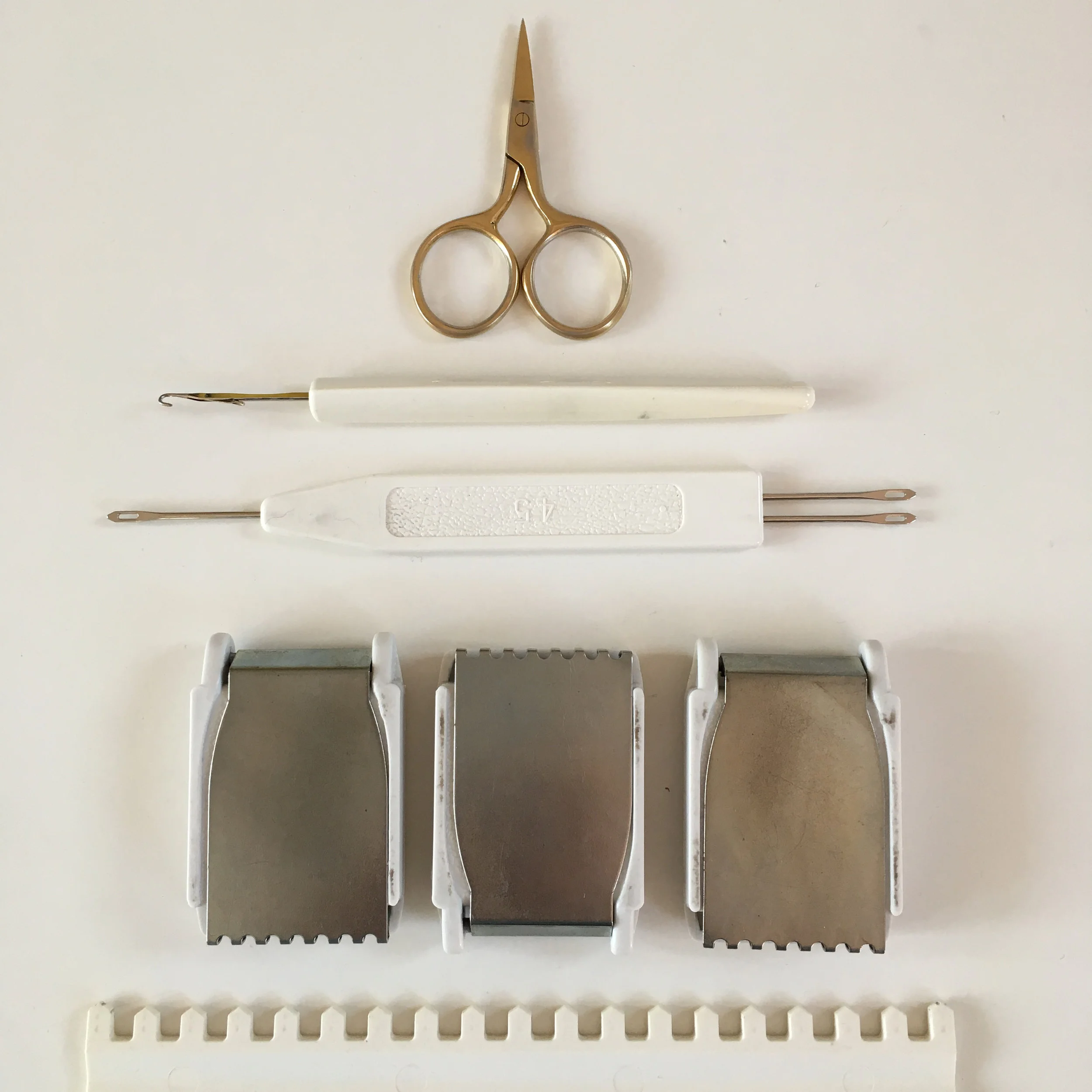

Tools used for knitting

The knitting machine, ready to go!

Hand Framed Knitwear, Knitted in our Scottish Borders Studio

For these lambswool hats, I use a domestic knitting machine. It's a bit different from my V-bed- it knits a heavier weight of fabric, and can knit different types of patterns. It's still a very hands-on process- I cast on each stitch, move the knitting machine carriage across for each row, and have to transfer stitches using the transfer tools you see in the photos. It requires precision!

Transferring stitches by hand.

Knitting in action- two colours at once to produce patterns

Sewing up the hat by hand

Hand Finishing Lambswool Hats

Once it has been knitted, each hat is sewn up by hand. This ensures a very smooth finish, and it's often hard to see the seam.

The wool beanie hats then need to be washed to remove any excess dye and allow the wool to mill up, which is also done by hand. The water is the Scottish Borders is very soft, which helps to make the knitwear feel amazing.

Once the hats are dry, they are pressed, and the labels are sewn on by hand. Then I get to start on the pom poms...

Hand washing the hat to remove excess dye

Pressing the hat- this ensures a flat fabric

Labels are sewn on by hand

Lambswool Pom Poms

Each pom pom is handmade. I use a pom pom maker, which makes life a lot easier than cutting out circles of cardboard (everyone has done that at some point though I hope)! Each pom has to be trimmed to neaten it up- I think I'm becoming an expert, and I can spend a surprisingly long time perfecting each one.

Making a wool pom pom- step 1

Trimming the pom to perfection

The finished lambswool pom. It's always tempting to keep trimming!

Then the pom pom is sewn onto the lambswool hat- it's the final step, and very satisfying once finished! It provides an extra pop of colour, so they often end up being brighter than the rest of the hat.

The finished Yarrow Hat.

A Luxuriously Soft Lambswool Bobble Hat

The finished hat has three layers of fabric over your ears to keep you snug and warm, and the combination of the lambswool and careful washing make it luxuriously soft- because being cosy is important!